The treatment and utilization of solid waste from magnesium metal involve many fields such as mechanical equipment, resources, and the environment. Currently, the comprehensive utilization rate of solid waste from the magnesium metal industry is low, especially for the utilization rate of magnesium slag, which is less than 30%. The long-term storage and delayed treatment of unutilized solid waste will gradually cause it to lose its activity, leading to difficulties in handling and occupying a large amount of land, resulting in environmental pollution problems. In severe cases, it can cause heavy metal pollution in soil and water.

Therefore, the comprehensive utilization of solid waste from magnesium metal products is an important part of the strategic emerging industry of energy conservation and environmental protection. It provides an important way to guarantee resources for industrial development that is both good and fast, as well as a fundamental solution to the environmental pollution and safety hazards caused by improper disposal and storage of solid waste. The comprehensive utilization of solid waste from the magnesium metal industry is an important measure to achieve industrial transformation and upgrading, and a long-term strategic policy to ensure the sustainable development of China's industry.

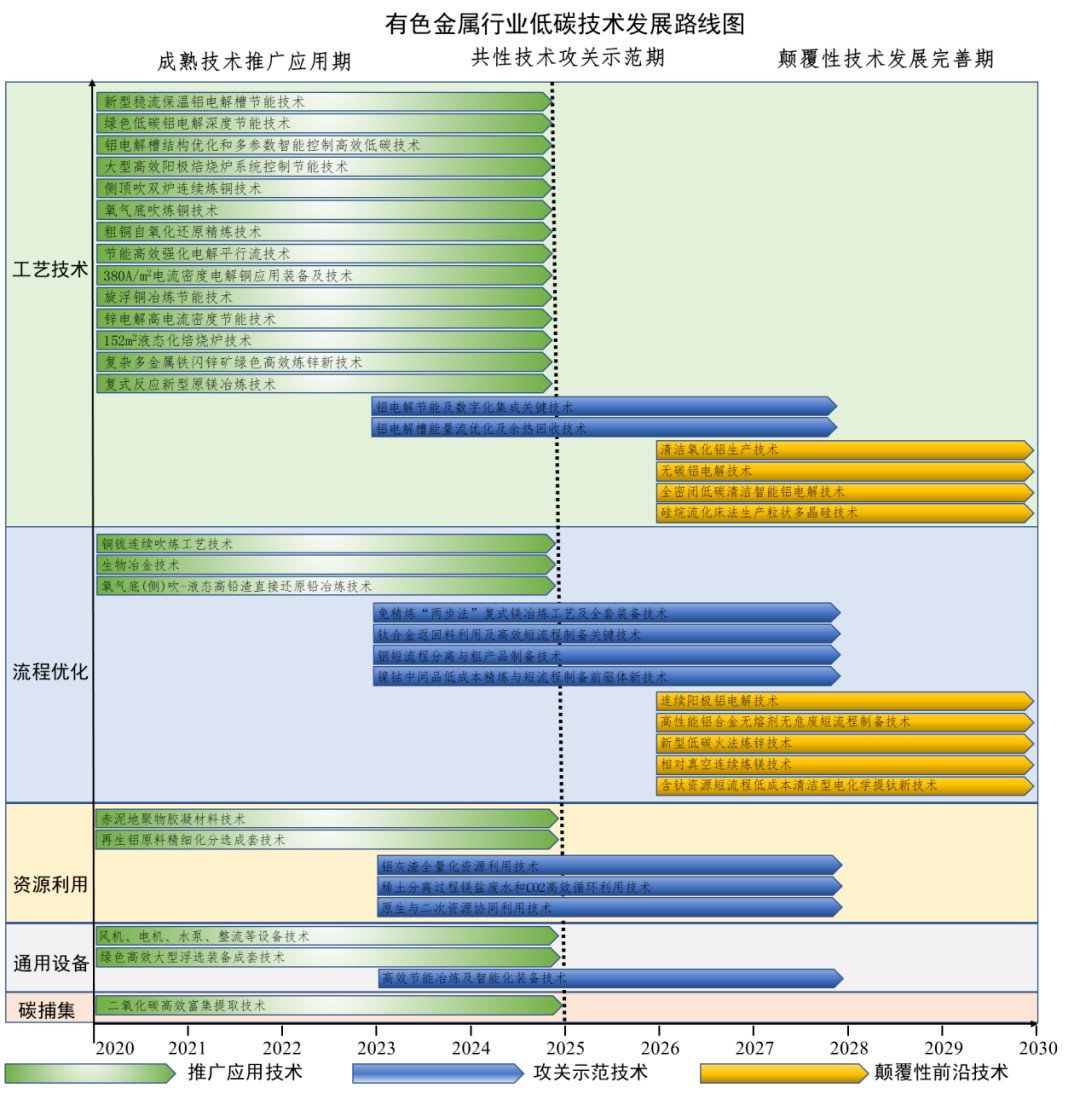

To implement the "Carbon Peak Implementation Plan for Nonferrous Metal Industry," the China Nonferrous Metals Industry Association organized the compilation of the "Low-Carbon Technology Development Roadmap for Nonferrous Metal Industry." It was officially released on March 3, 2023. The roadmap clearly defines the green and low-carbon technology paths for China's nonferrous metal industry to achieve a carbon peak, including process technology, process optimization, resource comprehensive utilization, general equipment, carbon capture, etc. The roadmap solutions for magnesium waste also highlight three categories and 38 technologies, focusing on promoting the application of green and low-carbon technologies, tackling common key technologies, and revolutionary cutting-edge technologies in the nonferrous metal industry. Among them, the dual-step process for magnesium smelting without refining and the complete set of equipment technology are included in the roadmap.

On January 31, 2018, "Magnesium-based Gel Materials" officially settled on the website of China Industrial Solid Waste Network - the national technology transfer platform for the comprehensive utilization of industrial solid waste.

Magnesium-based gel materials are composed of a ternary system of MgO-MgCl2(MgS04)-H2O. In actual production, it often requires the addition of modifiers and other functional materials to become a quaternary, quinary, or even a senary system. Wall materials made from magnesium-based gel materials are non-combustible and reach level A1. The material's toxicity and smoke hazard classification reach safety level AQ, and its fire resistance limit averages more than 1.5 hours, which is much higher than other materials such as gypsum, cement, and calcium silicate.

Compared with calcium-based cement products, the strength of magnesium-based gel wall materials can easily reach 62.5mPa, the impact resistance is increased nearly 5 times, and the frost resistance can be improved by more than 3 times. The fire resistance, mechanical strength, processability, production energy saving, and substrate compatibility index of magnesium-based gel products made of magnesium metal block are all higher than other board materials.

Magnesium-based gel materials can bond well with plant fibers, and the alkalinity is weak, so it will not corrode the fibers. It is commonly used to prepare magnesium-based gel wood pulp, which can be used to make magnesium-based gel wood-based panels for interior walls, ceilings, and floors. It can also be pressed into various parts for use as window sills, door and window frames, and stair handrails.

Magnesium-based gel materials are applied in solid waste treatment, including general solid waste treatment, solid waste disposal, building material preparation, handicraft preparation, and replacing large volume concrete. In hazardous waste treatment, they are mainly used for heavy metal fixation, building material preparation, and safe landfill. In functional material synthesis, they are used to synthesize adsorbents, sound-absorbing materials, insulation materials, waterproof and air-proof materials.

Producing one ton of magnesium will produce 6-7 tons of reduction slag, 0.1-0.2 tons of refining slag, and 0.2-0.5 tons of forging waste slag. Based on current estimates of magnesium production, the magnesium smelting industry produces more than 6.5 million tons of smelting waste slag each year. However, the problem of comprehensive utilization of magnesium slag has persisted for a long time. A considerable number of enterprises lack the objective conditions to use magnesium slag as a cement raw material, as well as advanced and applicable harmless treatment and resource utilization technologies, and can only occupy land for storage, posing significant risks to the environment and ecology.

In July 2021, Yulin City held a review meeting for the "Construction Plan of Yulin City's Large-scale Solid Waste Comprehensive Utilization Base". The plan proposed to build the Fugu Large-scale Industrial Solid Waste Comprehensive Utilization Zone in the east and west of Fugu County and deploy and implement solid waste filling and utilization projects such as coal gangue. The plan aims to rely on the Fengjiata Coal Mine in the east of Fugu, deploy solid waste filling projects such as coal gangue, and support the comprehensive utilization of solid waste such as fly ash, gasification slag, and magnesium slag of coal-electricity-chemical smelting enterprises such as Qingshui River Power Plant, radiating to other industrial areas of Qingshui and Huangfu 2 towns in the east of Fugu. It also aims to rely on the Guojia Bay Coal Mine in the west, deploy solid waste filling projects such as coal gangue, and support the comprehensive utilization of solid waste such as Guojia Bay coal mine gangue, as well as fly ash and desulfurization gypsum of Guojia Bay Power Plant, radiating to other industrial areas of Xinmin, Sandaogou, Laogaochuan, and Dachanghan 4 towns in the west of Fugu. Currently, in accordance with the requirements of the "Chain Leader System for Yulin City's Key Industrial Chains" (Yuban Letter [2021] No. 49), the city's Ecological Environment Bureau leads the promotion of the large-scale solid waste comprehensive utilization industrial chain to further promote the construction of existing industrial solid waste comprehensive utilization projects in Yulin City.

On February 23, the Shaanxi Provincial Department of Industry and Information Technology, the Shaanxi Provincial Development and Reform Commission, and the Shaanxi Provincial Ecology and Environment Department issued the "Implementation Plan for Carbon Peaking in the Industrial Sector of Shaanxi Province".

The plan emphasizes the strengthening of the recycling and utilization of renewable resources. It promotes the standardized management of the recycling industry for waste steel, nonferrous metals, waste paper, waste plastics, and scrap tires, encourages enterprises that meet the standard conditions to publish their carbon footprint. It also extends the industrial chain for the deep processing of renewable resources, promotes the efficient recycling and utilization of metal waste scraps such as steel, magnesium, and copper, as well as waste paper, waste plastics, and waste textiles, which led to competitive magnesium scrap price.

The notice also mentioned that the comprehensive utilization of industrial solid waste and technological innovation should be accelerated, and the high-value utilization of bulk industrial solid waste such as smelting waste, desulfurized gypsum, crystalline miscellaneous salt, magnesium metal slag, carbide slag, gasification slag, and tailings should be supported.

Magnesium slag is a solid waste discharged by magnesium metal plants during the magnesium smelting process. The process of producing magnesium metal is roughly as follows: calcining magnesite (MgCO3·CaCO3) in a rotary kiln (calcination temperature is 1,150-1,250℃), then grinding it into powder and mixing it with ferrosilicon powder (containing 75% silicon) and fluorspar powder (containing 95% calcium fluoride) to make balls (ball-making pressure is 9.8-29.4 MPa). The balls are then fed into a heat-resistant steel reduction vessel and reduced in a reduction furnace at a temperature of 1,190-1,210℃ and under vacuum conditions of 1.33-10 Pa to obtain crude magnesium. The crude magnesium is then refined by a flux, cast into ingots, and subjected to surface treatment to obtain magnesium metal ingots, and the remaining residue is magnesium slag.

A mineralizer made from magnesium slag is a substance added to the raw materials that can promote or control the formation or reaction of crystalline compounds. In the cement industry, mineralizers that can accelerate the formation of crystalline compounds are a small amount of additive for the raw materials that are easy to burn. The added mineralizer can activate the lattice by interacting with the reactants, thereby enhancing the reaction ability and accelerating the solid-phase reaction.

Using magnesium slag to produce building cement can replace some of the mineral slag used in producing blended cementitious materials. The cement produced from magnesium slag has relatively stable quality, but with an increase in the amount of magnesium slag added, there is a tendency for the early strength of the cement to decrease and the setting time to lengthen. Therefore, when using magnesium slag as a blending material for cement production, relevant technical requirements of national standards should be met.

Using magnesium slag as a desulfurizing agent is meaningful as the circulating fluidized bed boiler desulfurization technology mainly uses calcium oxide for desulfurization, and the mass fraction of calcium oxide in magnesium slag is about 50%. Studies have shown that with a Ca/S molar ratio of 3 for desulfurizing agent at 25.5% dosage, under equivalent conditions (particle size less than 0.105 mm, 900℃, φ(O2) of 5%, φ(SO2) of 0.2%, N2 as balance gas), the expected desulfurization efficiency can reach 76.5%. Analysis results show that the desulfurization effect is mainly related to factors such as the particle size, porosity, and desulfurization temperature of magnesium slag. Magnesium slag with a smaller particle size and higher porosity can improve the desulfurization efficiency of magnesium slag at an appropriate air excess coefficient and temperature.

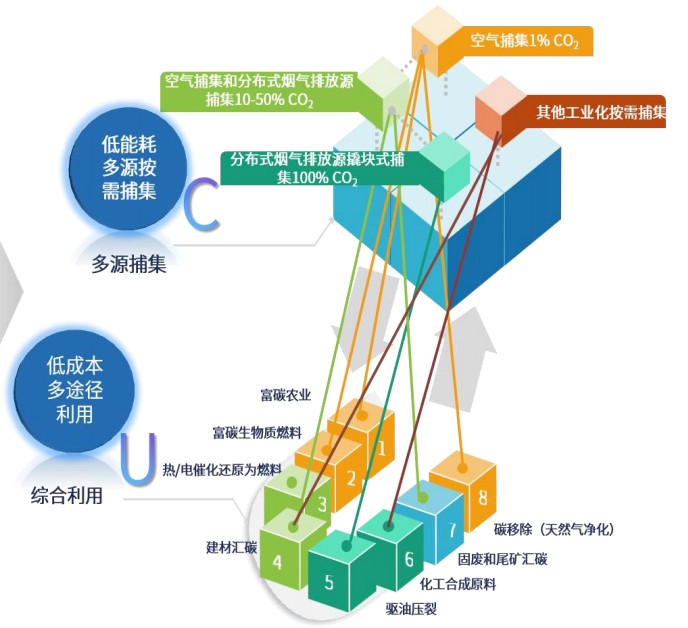

CCUS and DAC are the necessary paths to achieve carbon neutrality.

The left side of the balance: Engineering emissions reduction

Essentially, it reduces carbon emissions by converting old and new energy, which can only slow down the rate of CO2 accumulation in the atmosphere, but cannot stop its increase or reduce its concentration. Carbon neutrality cannot be achieved solely by relying on the left side of the balance.

The right side of the balance: Engineering carbon sequestration/carbon sink

Through the engineering capture, use, and storage of carbon dioxide via CCUS and DAC, atmospheric CO2 levels can be controlled, providing a "safety net" for the left side of the balance. Together, they can gradually move towards carbon neutrality.

CCUS - CO2 capture, utilization, and storage. It involves capturing carbon dioxide from flue gas and either utilizing or storing it.

DAC - Direct Air Capture technology, which directly captures CO2 from the air, is the only "negative emission" engineering technology that directly addresses climate change.

CCU plan for alkaline solid waste carbon sequestration:

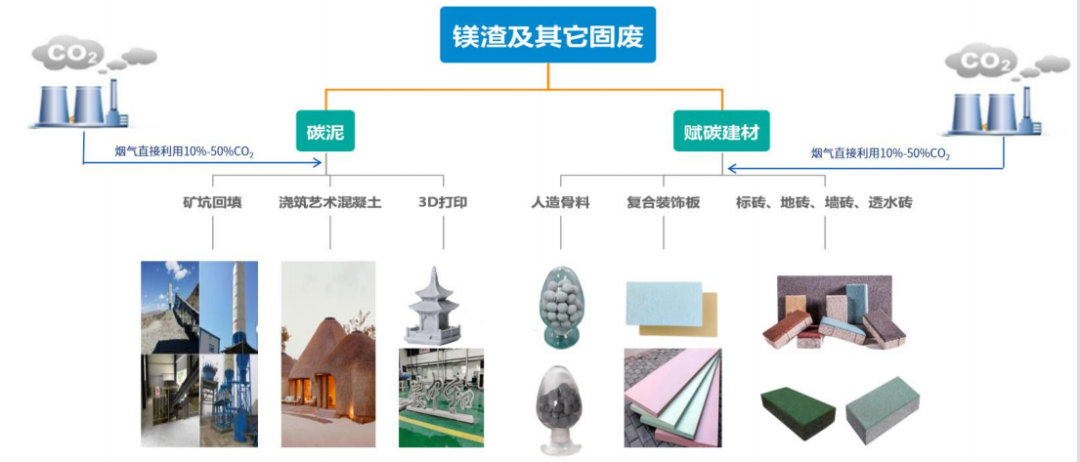

Alkaline solid waste has good permanent carbon sequestration capabilities, and only requires low to medium concentration of non-pure CO2 to achieve carbon sequestration and carbon sink. Currently, the concentrated emissions from centralized sources such as thermal power plants can be directly utilized, making it very suitable for a distributed CCU output mode.

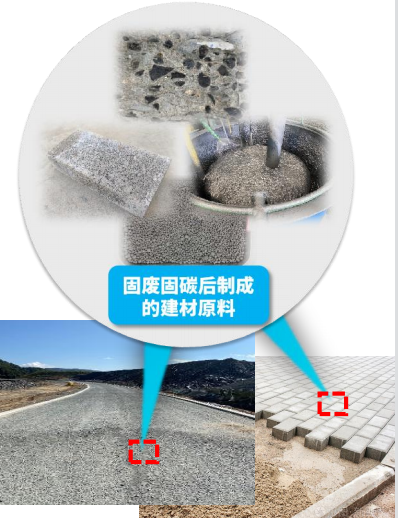

After carbon sequestration of alkaline solid waste, it can be further processed into value-added green carbon sequestration building materials such as building aggregates and solid waste-based composite binders, achieving resource utilization and achieving the triple benefits of waste treatment, carbon sink, and resource utilization.

Technical advantages:

By utilizing the mineralization principle, the CO2 emitted from the kiln flue gas of carbon-emitting industries such as thermal power, steel, chemical and cement can be directly utilized. This not only reduces the alkaline solid waste category, such as magnesium slag, but also produces high value-added products. It achieves the triple benefits of reducing emissions and carbon, recycling solid waste resources, and turning waste into treasure.

We have developed unique world-leading multi-form carbon utilization technologies, such as alkaline activator technology for alkaline solid waste, carbon sequestration building materials based on solid waste, and carbon sequestration mine backfill and mine restoration technology. By forming a series of industrial flue gas and alkaline solid waste synergistic resource utilization pathways, we achieve harmless and resource-based treatment of solid waste, and permanently sequester CO2 at the same time.

From the perspective of the upstream and downstream of the hazardous waste treatment industry value chain, the upstream of solid waste treatment mainly includes the production and manufacture of various solid waste treatment and transportation equipment. The midstream includes the processing of various solid wastes, which are mainly classified into three categories: resource recovery, incineration, and landfill treatment, in China. The downstream of solid waste treatment is the end market of solid waste treatment, mainly referring to the treatment of wastewater and fly ash generated in the process of solid waste treatment.

In the upstream field, the supply of solid waste treatment equipment mainly includes transportation and treatment equipment. The manufacturing industry of various solid waste transportation equipment provides basic conditions for solid waste treatment. Representative enterprises of transportation equipment include Dongfeng, Jiefang, Foton, Zhongqi, Qingling, and Jiangling. Representative enterprises of solid waste treatment equipment manufacturing include Huagong Technology, Anjule, Lvjing Environmental Protection, Bangguan Machinery, Shuitianlan Environmental Protection, and Sansheng Environmental Protection.

In the midstream of solid waste treatment field, according to the different types of solid waste treatment, it can be roughly divided into industrial solid waste treatment, kitchen waste treatment, and hazardous waste treatment. In the field of industrial solid waste treatment, representative enterprises include Dongjiang Environmental Protection, Conch Venture, Yajule Environmental Protection, Xuelang Environment, and so on. In the field of hazardous waste treatment, representative enterprises include Everbright Environmental Protection, Green Power, Shanghai Environment, and so on.

In the downstream end disposal market, representative enterprises of fly ash solidification treatment include Wuxi Kerui, Zhongke Guorun, Fuercheng Environmental Protection, and Ente Heavy Industry. Representative enterprises of wastewater treatment include Tianze Environmental Protection, Ruimedi, WoTong Environmental Protection, and Hongchun Environmental Protection.

To promote carbon emission reduction throughout the entire process, including energy utilization, raw material use, process optimization, equipment renewal, and transportation methods, enhance the global market competitiveness of the magnesium industry, advance the clean production and high-end product development of magnesium alloy materials, we still have a long way to go.